FRP

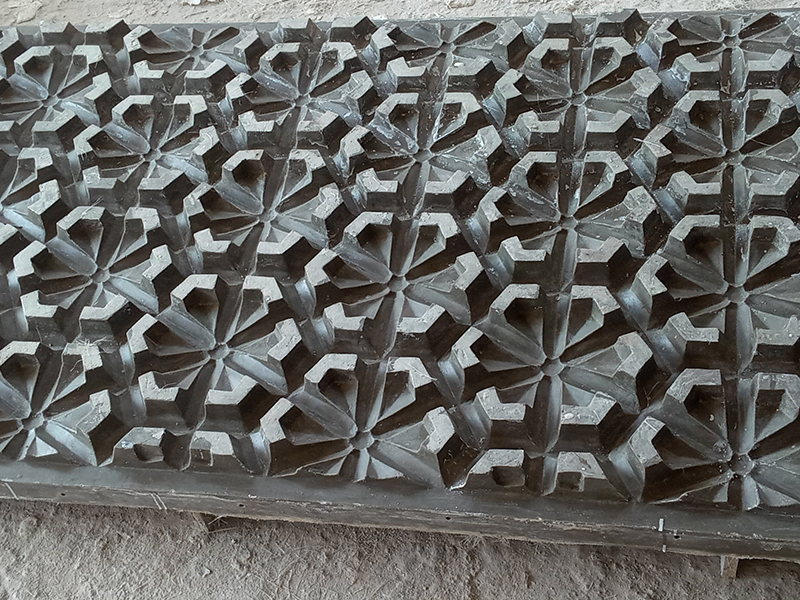

FRP (Fiber-reinforced Polymer)

SHREE GRC one of the India’s leading manufacturers of Fibre Reinforced Plastics (FRP) products Throughout its network of operations the company has the resources and experience to service a complete range of projects whatever the complexity or size.

Fibre-reinforced plasticsare best suited for any design program that demands weight savings, precision engineering, definite tolerances, and the simplification of parts in both production and operation. A molded polymer product is cheaper, faster, and easier to manufacture than a cast aluminum or steel product, and maintains similar and sometimes better tolerances and material strengths.

-

01Anti Corrosive Property

FRP is anti-corrosive and the sole reason for using fiber-glass-reinforced plastics (FRP) is that they are primarily corrosion resistance. Also, FRP is the only materials that will handle an intense service environment.

-

02 Lightweight

FRP is light in weight and has a substantially low weight to strength ratio and needs one-seventh in quantity as against steel and concrete and required half in weight as aluminum

-

03Strong

Fiberglass reinforced plastic( FRP) is strong and useful in forming equipment for the various application with varying use in missile or boat or bathtubs.

-

04Pocket-friendly

FRP is economic and pockets friendly from the manufacturer's point of view and affordable over other material to be used otherwise

-

05Flexible

FRP is flexible in nature and this quality makes it favorable over other material like steel

-

06GLabor -cost-effective and easy to install

Advantage of FRP is that it helps in cost-effectiveness on the labor front and during installation also.

-

07 Speeds up construction

FRP helps to increase the speed of construction of equipment and requires less time from the construction point of view.

-

08Reliable and Durable

FRP is reliable in nature and has longevity over steel and aluminum and yet gives more durable efficient service life and reduces replacement and maintenance.

-

09Negligible Heat Conductivity

FRP is known as non-conductor of heat thus makes FRP first preference in industrial usage

-

10A bad conductor of electricity.